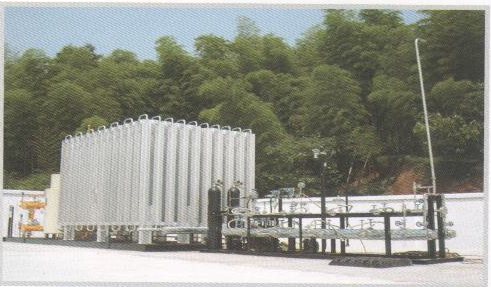

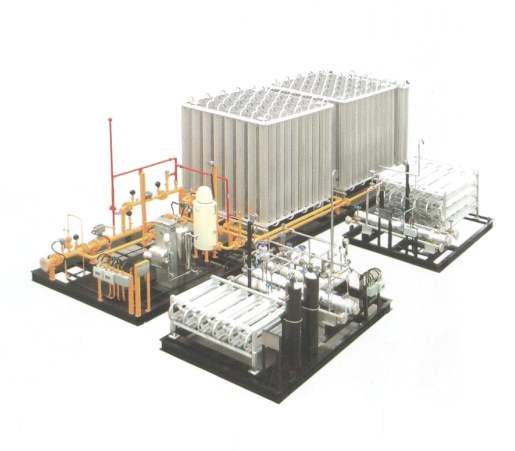

Skid mounted LNG gasification station integrates unloading pressurization, tank pressurization, gasification pressure regulation, metering and odorization into one LNG supply terminal.

unloading pressurization, tank pressurization, gasification, pressure regulation, metering, odorization,

Electrical control and other functions are integrated

compact structure, small floor area

support remote monitoring, realize unattended

adopt air temperature gasification to reduce operation cost

skid mounted integrated type, convenient installation and short construction period;

simple operation and maintenance;

the equipment has strong mobility and can be used many times and repeatedly

equipped with low-temperature liquid-phase safety valve, gas-phase safety valve and safety relief valve

equipped with liquid phase low temperature emergency shut-off valve

equipped with gas phase overpressure shut-off valve

it is equipped with static grounding, and all wiring of field instruments are collected into explosion-proof junction box.

equipped with electric heating water bath reheater to ensure normal operation of polar temperature

all pressure, temperature, liquid level and flow signals are linked with the monitoring system to ensure the safety of the station

| Specification type | Skid outline (wxlxh) mm | Size of gasifier (WxLxH) mm | Remarks | ||

|---|---|---|---|---|---|

| A pry | B pry | C pry | |||

| ARTLNG-200 | 3300x2000x2700 | 3500x2000x2700 | 6500x2300x2700 | Gasifier skid | |

| ARTLNG-300 | 3300x2000x2700 | 3500x2000x2700 | 7930x2300x2700 | Gasifier skid | |

| ARTLNG-400 | 3300x2000x2700 | 3500x2000x2700 | 8950x2300x2700 | Gasifier skid | |

| ARTLNG-500 | 3300x2000x2700 | 3500x2000x2700 | 9950x2300x2700 | Gasifier skid | |

| ARTLNG-600 | 3300x2000x2700 | 3500x2000x2700 | 11000x2300x2700 | Gasifier skid | |

| ARTLNG-700 | 3300x2000x2700 | 3500x2000x2700 | 4200x2300x2700 | 1575x1440x5345 | Gasifier not skid |

| ARTLNG-800 | 3300x2000x2700 | 3500x2000x2700 | 4500x2300x2700 | 1575x1950x5345 | Gasifier not skid |

| ARTLNG-1000 | 3300x2000x2700 | 4000x2200x2700 | 4500x2300x2700 | 2290x1950x5345 | Gasifier not skid |

| ARTLNG-1200 | 3300x2000x2700 | 4000x2200x2700 | 5000x2300x2700 | 2290x2205x5345 | Gasifier not skid |

| ARTLNG-1500 | 3300x2000x2700 | 4000x2200x2700 | 5000x2300x2700 | 2290x1950x6545 | Gasifier not skid |

| ARTLNG-2000 | 3300x2000x2700 | 4000x2200x2700 | 5500x230x2700 | 2190x1950x9545 | Gasifier not skid |

| ARTLNG-2500 | 3300x2000x2700 | 4000x2200x2700 | 6000x2300x2700 | 2190x2460x9545 | Gasifier not skid |

| ARTLNG-3000 | 3300x2000x2700 | 4000x2200x2700 | 6000x2300x2700 | 2190x3480x9545 | Gasifier not skid |

| ARTLNG-4000 | 3300x2000x2700 | 4000x2200x2700 | 6500x2300x2700 | 2190x3735x9545 | Gasifier not skid |

| ARTLNG-6000 | 3300x2000x2700 | 4000x2200x2700 | 6500x2300x2700 | Combination of above vaporizers | Gasifier not skid |

| ARTLNG-8000 | 3300x2000x2700 | 4000x2200x2700 | 8000x2300x2700 | Combination of above vaporizers | Gasifier not skid |

| ARTLNG-10000 | 3300x2000x2700 | 4000x2200x2700 | 8000x2300x2700 | Combination of above vaporizers | Gasifier not skid |

Note:

Skid A is unloading pressurization skid, skid B is storage tank pressurization skid, and skid C is gasification, pressure regulation, metering and odorization skid.

If the gasification volume is less than 600nm3 / h, the same skid shall be used for gasification, pressure regulation, metering and odorization.

Product application

◆urban and rural residential areas

◆ population concentration in remote areas

◆ commercial, catering and other users

Gas boiler users

industrial users such as ceramic factory, hot rolling factory, aluminum profile factory, etc.

gas power plant